Ultrasonic Pulse Velocity

Ultrasonic Pulse Velocity (UPV)

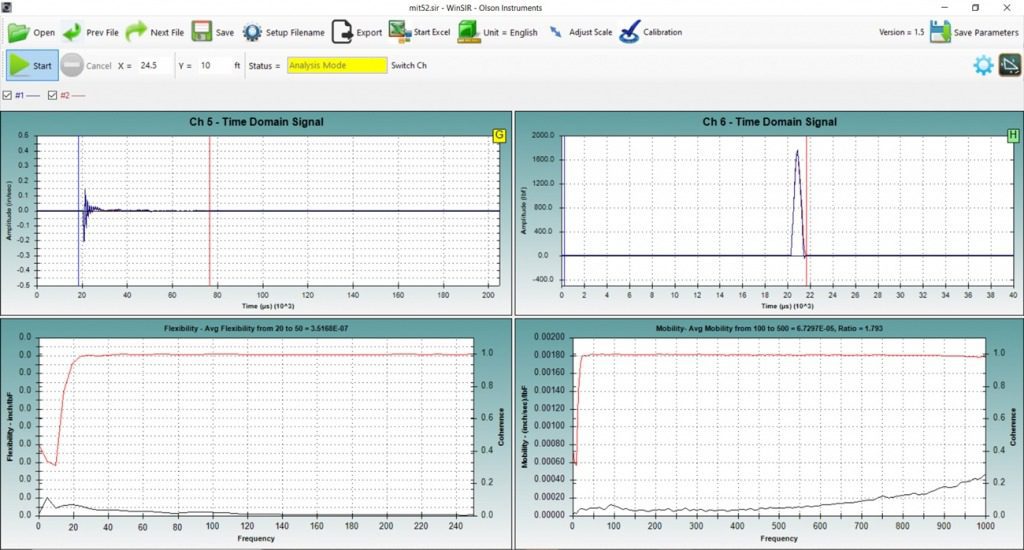

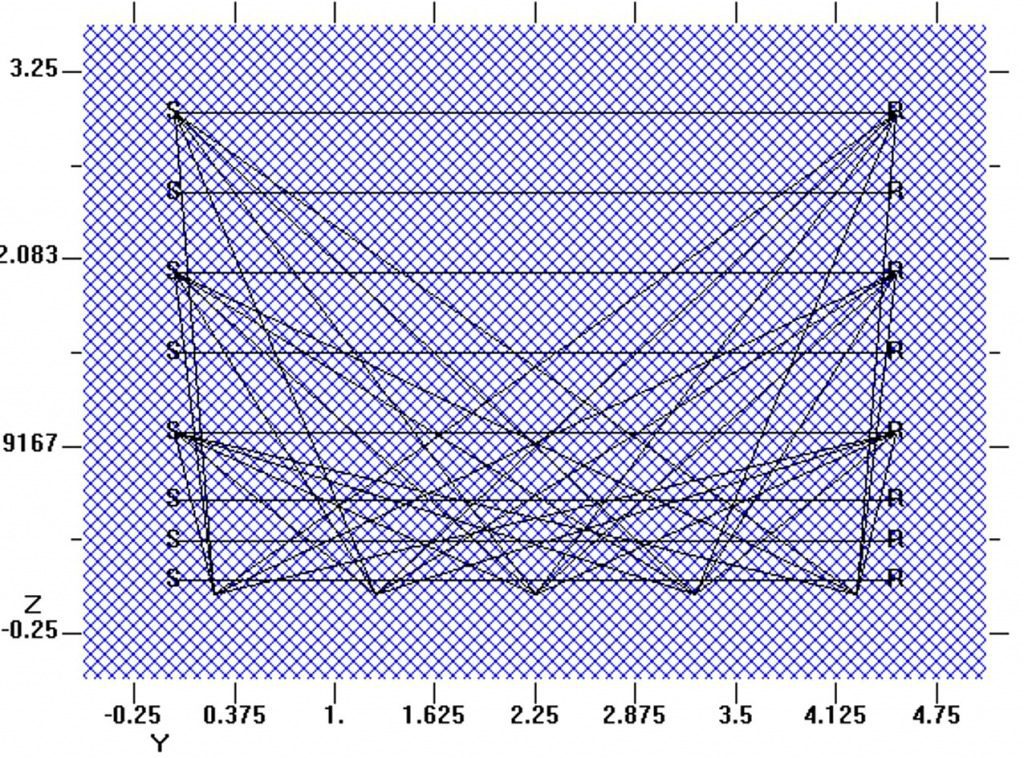

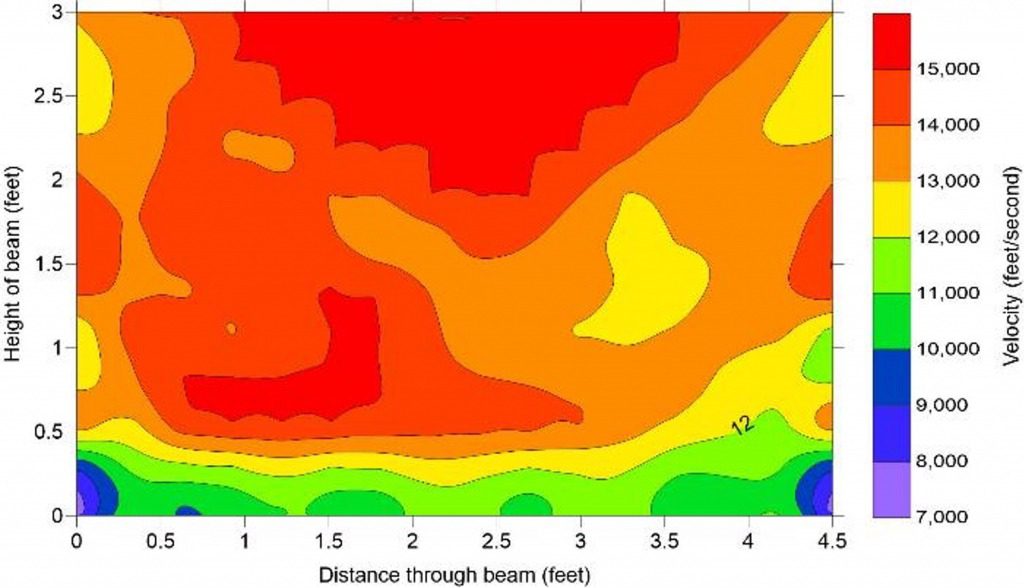

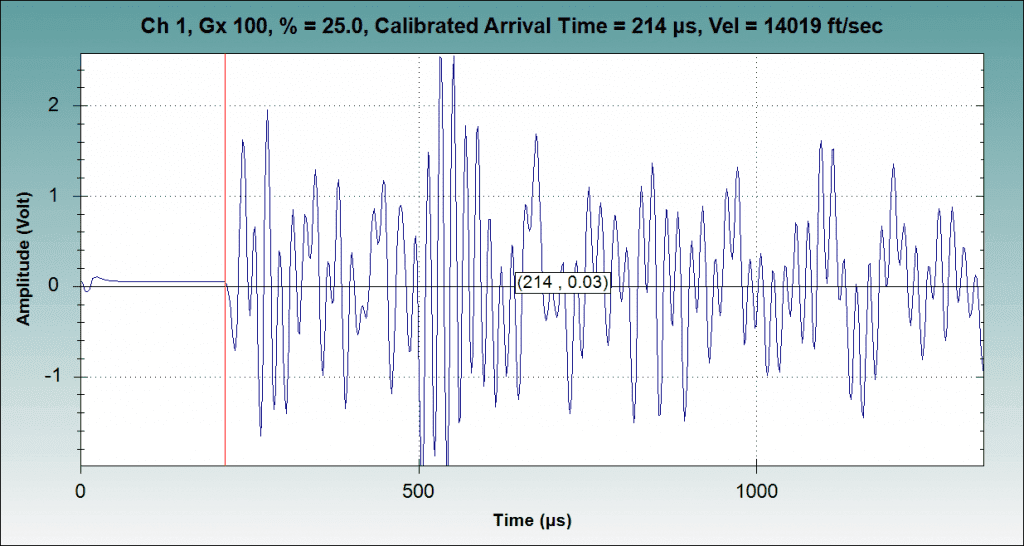

Ultrasonic Pulse Velocity (UPV) testing is used to determine the integrity and quality of structural concrete or stone (up to 6 feet thick) by measuring the speed and attenuation of an ultrasonic wave passing through the element being tested. Areas with lower velocities typically have lower density and strength relative to high velocity areas. Data collected along multiple test paths can be used to create tomographic images of defects.

- Identify voiding, honeycombing, cracking and other defects

- Identify areas of low-quality concrete

- Define the size and shape of a defect by using multiple test paths

- Two-sided access required for direct-path testing

- Test around corners when complex geometry precludes direct-path testing, such as at beam intersections

- Test across a surface for surface-opening crack depth measurements

Sonic Pulse Velocity (SPV)

Sonic Pulse Velocity (SPV) testing is used at lower frequencies for distances greater than 6 feet, such as large columns, beams, and dams.

- Test concrete, stone, or wood members up to 25 feet thick

Applicable on:

- Elevated Slabs

- Columns

- Beams

- Dams

- Members with Two-Sided Access

Test for:

- Voids

- Honeycomb

- Cracks

- Delaminations

- Strength of Early Age Concrete

The UPV System

Ultrasonic Pulse Velocity (UPV) investigations are performed to assess the condition of structural members if access to both sides is available.

- Quality Assurance

- Determine the integrity of structural concrete

- Diagnose Defects

- Identify and map voids, honeycomb, cracks, delaminations, and other damage

- Test New Pours

- The UPV system can predict the strength of early age concrete

- Variety of Materials

- Test on concrete, wood, masonry, stone, ceramics, and metal materials

- Testing Options

- The two surfaces used for testing can either be a direct transmission, semi-direct transmission, or an indirect transmission

Image Gallery

All Methods