Impact Echo

Impact Echo

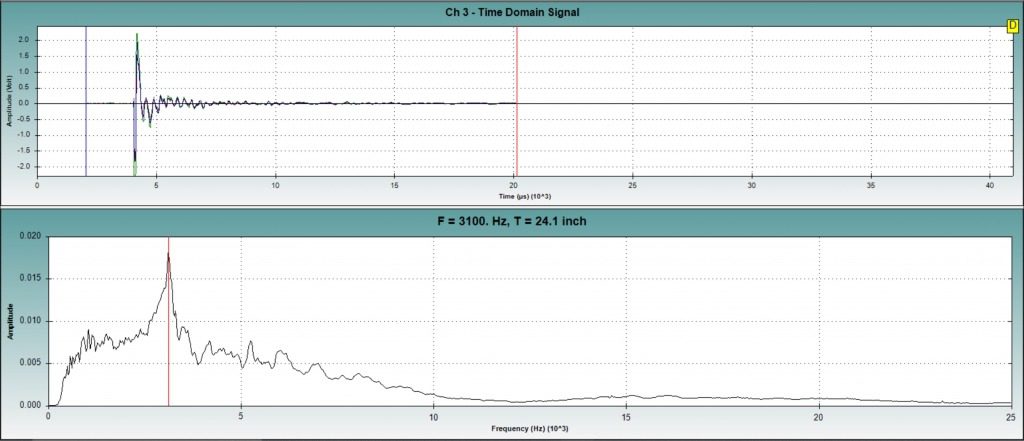

The Impact Echo (IE) method is used for rapid flaw detection and thickness evaluation of concrete and masonry structural materials.

- Applicable for parallel to subparallel flaws from the surface in plate-like objects such as slabs, walls, columns, mat foundations, beams

- One-sided testing

- Flaw location and depth

- Thickness profiling without the need to drill, core or excavate

Impact Echo Scanning

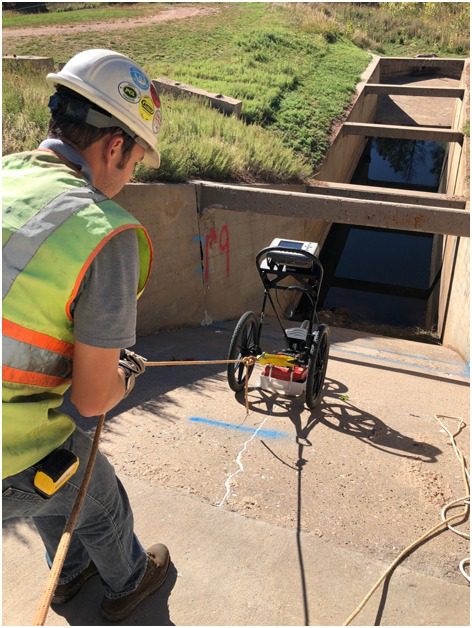

A variation of the impact echo principle is the Impact Echo Scanning (IES) method.

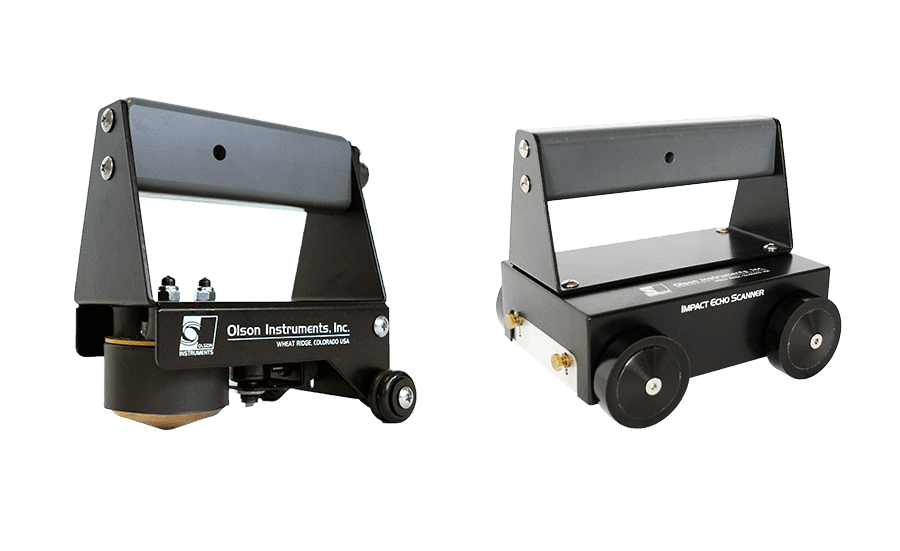

- Patented technology of a rolling transducer and automated impactor for near-continuous IE testing

- Fast-acquiring IE testing (1000 points/hour)

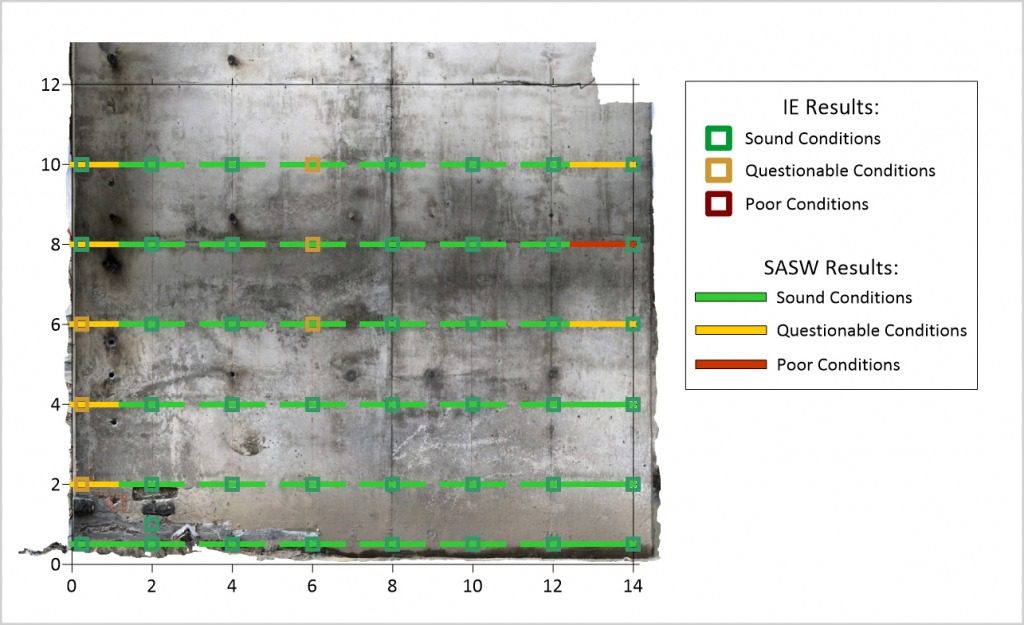

- Best for high resolution imaging of large areas for internal concrete conditions

- Example applications: slab thickness profiling and flaw detection, pavement testing, location of ungrouted sections of post-tensioning ducts

- Read a paper on the IES, as applied to PT duct void location

Applicable on:

- Floors

- Beams

- Runways

- Tunnels

- Dams

- Columns

- Walls

- Pavements

- Slabs up to 24 Inches (60 Centimeters) Thick

Test for:

- Thickness and Internal Cracks

- Voids

- Honeycomb

- Delaminations

The IE & IES Test Systems

The Impact Echo (IE) system is designed to determine the condition and thickness of concrete, wood, stone, and masonry structural members when voids, honeycomb, and/or cracks are suspected.

- High Data Acquisition

- Thousands of tests can be performed per hour when “imaging” of internal concrete conditions is required

- Convenience

- Only one side of the structure needs to be accessible for testing

- Rapid Testing

- Rapid flaw detection and thickness evaluation

- Testing Specificity

- The IE method provides information on the depth of a flaw or defect, in addition to mapping its lateral location and extent

- Variety of Materials

- This system can be used on concrete, stone, and masonry materials

Image Gallery

All Methods